Hexagon’s Mining and Autonomy & Positioning divisions are teaming to further automate mining, agriculture and other heavy industries to help make them more efficient and sustainable, the leaders of those units said during the HxGN Live 2023 conference in Las Vegas.

“Why are we here today?” asked Maria Luthström, president of Autonomy & Positioning. “It’s two diverse portfolios coming together with one common goal—it’s to autonomize heavy industry, make it more efficient, safe and profitable. And at the same time, we’ll also make it sustainable, and we all know that the way we’re consuming today isn’t sustainable.”

“We are so proud about the formation of our partnership and what it means for you,” said Nick Hare, president of the Mining division. “What this really means is enabling autonomy at scale, making it simple, making it easy to use, giving access to all and pushing further ahead, because we can and we need to do more.”

He said there’s been a lot of progress in green energy, but “in my lifetime alone, we’ve emitted more carbon than all [the history of] mankind.…So, I think we need to talk about the bigger question here.”

Hare noted it requires 70 liters of water to produce one pint of beer, and there are more than 60 different types of metals in smart phones. “That’s 60 more holes in the ground somewhere in the world that we’re digging deeper…and we have more every year. How are we going to maintain that?”

Luthström agreed. “We’re clearly not going to stop consuming beer or social media. So, the demand for resources is just going to continue growing and growing. So, how do we reduce the impact on the environment? We have to reduce the impact per unit of consumption, and that we do with disruptive technology.”

In agriculture, for instance, she said the use of precision technology is “enabling farmers to produce more in the same amount of land, increasing crop yield and reducing chemicals and water. And that is truly sustainable.”

Then there is mining. Hare said the mining industry has the perception of being traditional, but it’s “actually further ahead in autonomy than any other…I guess the question is, can we do more, can we go faster, is there something new and interesting?”

One of Hexagon’s signature projects is automated ore hauling for Mineral Resources Ltd. in Western Australia, a remote location where there is an acute worker shortage. The solution from Hexagon’s Mining and Autonomy & Position division is an autonomous road train, which will cut down on maintenance costs and boost safety.

In a separate panel discussion, Andrew Crose, vice president, autonomous and managing director, EMEA, of Hexagon Mining, said given the shortage of long-haul drivers, “the mine is not feasible unless we do this.” The $3 billion project is set to open next year.

Crose said it makes sense to start with automating more mining operations because their equipment is in use more often. Mining vehicles are in operation 70% to 80% of the time, versus a civil construction excavator, which might have a 20% to 30% rate, or large agricultural vehicles, which are primarily used at planting and harvesting.

“They have the highest application rate,” Crose said of mining vehicles.

Mining also is an industry where autonomy can boost safety. “It’s a much safer industry than it was 200 years ago, but it’s not the safest in the world,” Crose said. With tele-operated remote excavators, autonomous trucks and autonomous surveying operations, “in five to 10 years, we could be at that goal of having nobody in the mine.”

During her presentation, Luthström said, “We need the whole of the industry to come together, a diverse set of industry to come together to solve this challenge and disrupt and make the big change. We know that autonomy is going to play a huge part in the equation to make this world more sustainable, and this we need to do so that we can continue mining and farming on this Earth for many generations to come. But maybe, maybe in the future we’ll actually be able to mine on Mars.”

Precision Landing

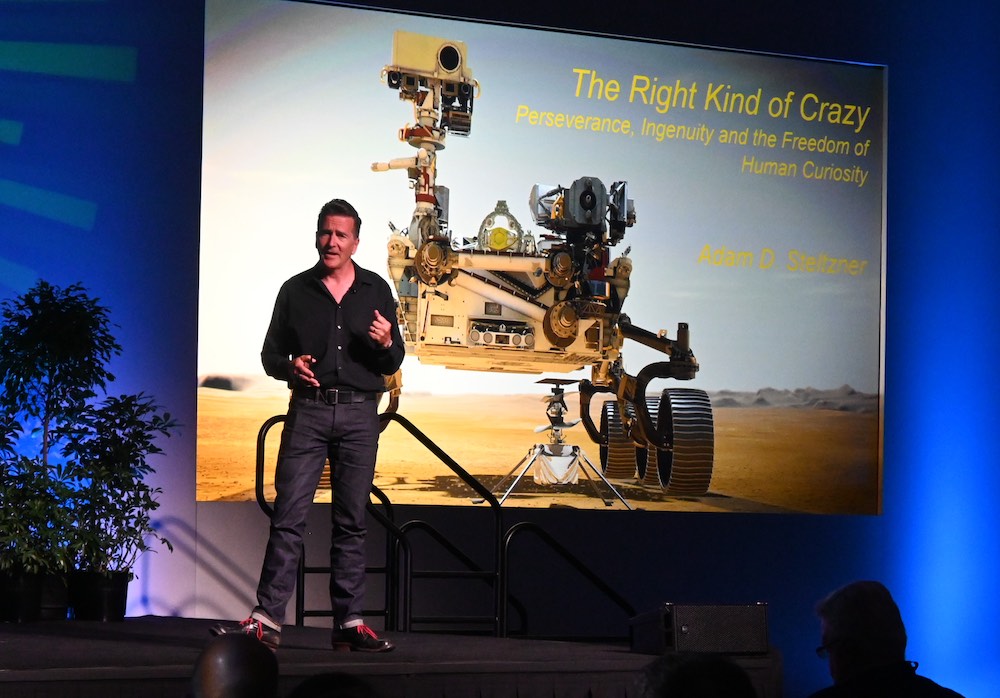

Luthström was referring to a presentation from another speaker, Adam Steltzner, the leader and chief engineer of the Mars 2020 mission that put the rover Perseverance on the red planet, an astonishing feat of positioning.

“She is actually mining, as we speak, on the surface of Mars,” he said, seeking signs of ancient life in a world that once contained water.

NASA’s Mars rovers have steadily (if not rapidly) increased in size and capability, from the 25-kilogram Mars Pathfinder in 1997 to the 175-kilogram Mars Exploration Rovers in 2004 to the Curiosity and Perseverance rovers of 2012 and 2020, which weigh 900 and 1,025 kilograms, respectively.

Steltzner described the latter two as “big, beautiful, nuclear-powered mega rovers” that touched down on the surface of Mars using an innovative sky crane, the final step in a process that slowed them from 13,000 miles per hour when they hit the thin Martian atmosphere to less than 10 miles per hour when they touched down to “the rough kiss of the Martian surface.”

Perseverance is now near the remnants of an ancient river delta, drilling core samples and putting them in hermetically sealed sample tubes that will be returned to Earth within the next decade.

“Our vehicle’s autonomous, just like some of yours might be in the mines,” he told the audience. Operators provide waypoints but the rover moves on its own path, monitored by satellite orbiter overflights and accompanied by the plucky Mars helicopter Ingenuity. (Ingenuity, a small VTOL drone, would have achieved full mission success with five flights but now has racked up 10 times that many.)

Eventually, 30 samples will be returned from Mars, about 500 grams worth of material that could answer the question of whether Earth’s closest neighbor once harbored life. And, Ingenuity has been so successful that NASA has added helicopters to the follow-on mission that will bring back the samples.

“The success of this technology demonstration has changed our business model and how we’re moving forward,” Steltzner said.

The question of why humans explore isn’t because it’s convenient or safe, he said. “We’re driven to explore despite the danger. We’re looking for the edge of what we can do. What is our potential?”