One prime mover, three trailers, 320 tons of ore, a 200-km trek – and no human driver. While that might sound futuristic to some, in Western Australia, it’s fast becoming reality.

Through a unique program for Mineral Resources Limited, Hexagon’s Mining division and Hexagon’s Autonomy & Positioning division have combined expertise and advancements to develop an autonomous road train to support ore hauling. This motorcade of mining material will soon have the ability to operate without human intervention across an entire scope of action from loading ore at the mine through the long distance haul to delivery of the material at the port. At total capacity, Mineral Resources expects to have more than 120 automated prime mover trucks by mid-2024 with the goal of full autonomy by 2025.

Behind the scenes of this distinctive program, the focus is largely on developing assured safety across an autonomous system of systems—rather than a single autonomous machine. Each vehicle in the train must be synchronized to move and react with better than human responsiveness across a changing landscape.

“It’s a harmonization of autonomous systems all operating in the broader context of a very long operational environment,” Justin Puent, product manager at Hexagon | AutonomouStuff, explained. “These machines must work together with awareness between the machines and with the surrounding environment. Accuracy and responsiveness is essential.”

Redundant Interactions

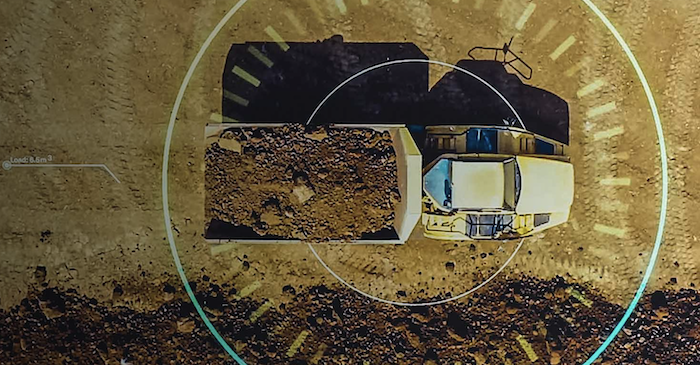

The heart of the autonomous platooning system is Hexagon’s integrated autonomy technology stack, a solution that brings together drive-by-wire technology with an autonomous management system to orchestrate vehicle movement in road train haulage. It’s a one-of-its-kind implementation with three critical features: drive-by-wire, perception and positioning.

In terms of positioning, the goal is 10 centimeter accuracy. “While you could argue that we will not need quite that fine of an accuracy every step of the way, there are areas such as tunnels, loading/dumping sites that need to be very precise,” added Puent. “The subsequent interaction with external sources requires elite corrections, redundancy and even antennas equipped with anti-jam technologies, because jamming is going to be a potential issue around population centers.”

The road train perception system relies on vehicle-to-vehicle communication with radar, where the instrumented vehicles around the road train will send positions to adjacent machines. The perception system uses ultra-wide band radios to determine the location of nearby tagged workers and other machines.

Confident Responsiveness

The Hexagon patented PACMod system reads and emulates analogue, pulse width modulation and digital signals to tap into the steering, braking, shifting and acceleration systems—and even the windshield wipers. The system further leverages advanced collision avoidance systems. Every element is essential especially when considering that these road trains might take a full kilometer to slow down. Therefore, the entire vehicle dynamics and particularly the object detection systems must operate without fail.

Puent confirmed, “The safety challenge is extremely significant. The sensors must be able to see an object from a long way away. That’s the kind of technology advancements that we are spending considerable time configuring, testing and improving.”

The system also requires hardened, ruggedized components that will work in the harsh environment of Western Australia. For instance, Puent points to the development of custom redundant actuators designed for this environment to steer the vehicle. “To make an autonomous road train a reality requires a fusion of design, operational process and technology—and we’re well down the road in delivering an optimal solution,” he said.

To learn more about the autonomous road train’s consolidated tech stack that incorporates one sensor set, one computing platform and one UI experience, all to achieve assured safety, join Justin Puent, Senior Project Manager at AutonomouStuff, a brand of Hexagon’s Autonomy & Positioning division at HxGN LIVE Global 2023 in 12-15 June in Las Vegas Nevada. Click here to register.