AEye Inc. leveraged its software-defined lidar architecture to improve sensor range by 20% and increase spatial resolution by 400%, extending its high-speed small-obstacle detection capabilities while enabling the same hardware to address hazardous vehicle cut-ins. The latest addition to its 4Sight intelligent sensing product line, called 4Sight+, is said to deliver industry-leading path-planning, obstacle avoidance, and prediction capabilities in an all-in-one solution for automotive OEMs.

The data fidelity and range upgrades are said to bring an increased level of dependability, performance, and adaptability to help OEMs eliminate phantom braking, improve existing ADAS features, and safely enable hands-free driving at highway speeds.

“These new capabilities were achieved entirely through firmware and software changes, using new algorithms and calibration techniques; this is just the tip of the iceberg of what we can do with software,” said Matt Fisch, AEye’s new CEO and Chairman. “Automakers are on a fast track to deliver intuitive, reliable ADAS services that improve safety. Our architecture allows us to match their timeline and brings OEMs and our partners, like Continental, one step closer to achieving their mission of ‘Vision Zero’—zero fatalities, injuries, and accidents.”

The new offering takes advantage of the 4Sight platform’s modular, bistatic system, with separate transmit and receive channels, that enables reconfiguration of lidar performance on-the-fly and adds new capabilities via over-the-air updates. Powered by a small MEMS (micro-electromechanical system) device that allows for ultra-fast yet robust movements, the platform is designed to be highly programmable to meet performance requirements for both urban and highway driving using a single platform.

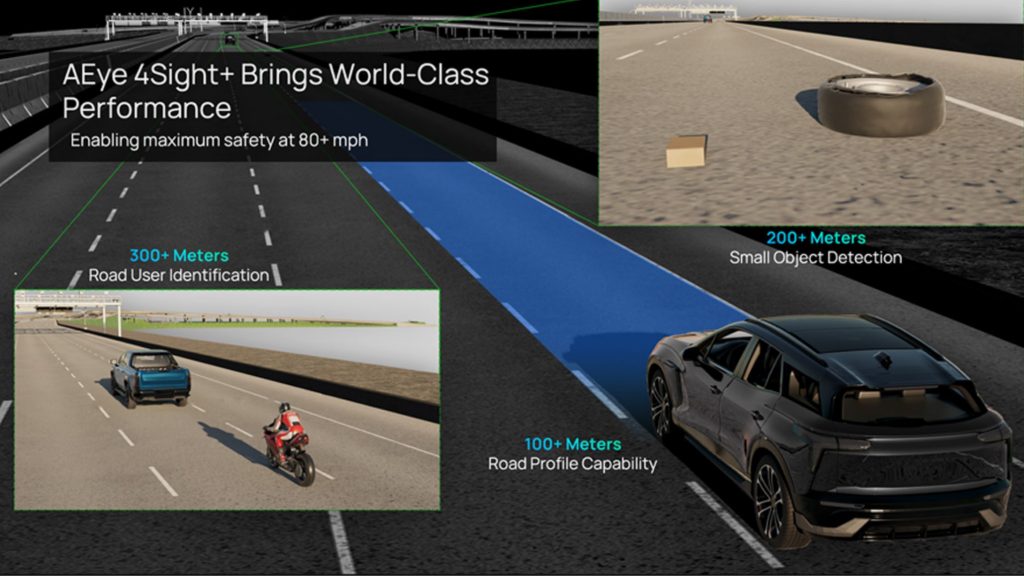

The 4Sight+ improves prediction capabilities by tracking vulnerable road users, including pedestrians and cyclists, as well as other vehicles at up to 300 m (980 ft). The solution improves reaction time by detecting small objects, like bricks and tires, at up to 200 m (650 ft). It helps with vehicle path planning by identifying road surfaces, such as cement and asphalt, at up to 100 m (330 ft), including in direct sunlight and low-light environments. These advantages enable predictive safety systems for a smoother, more comfortable hands-free driving experience at more than 80 mph (128 km/h) without requiring driver intervention.

Another advantage of a software-defined sensor is that it allows OEMs to leverage AEye’s scanning agility to reconfigure the lidar’s performance instantaneously. It can use cues from other sensors in the vehicle, such as speed or GPS location, to activate defined modes of operation for parking, urban, and highway environments.

By optimizing lidar performance based on driving conditions, the sensor continues to achieve high performance, while operating at the lowest power required. It also allows for flexibility in form factor—an important consideration for vehicle integration as OEMs pursue more efficiency for electrification.

Nearer to production, AEye’s biggest design win to date, with Tier One supplier Continental, was on display at CES 2023. AEye’s ShadowVan demonstration vehicle featured Continental’s HRL131 long-range lidar built on 4Sight. Its smart software can compensate for sensor pitch in real time, a critical capability in a world where roads are variable. The roof-mounted lidar featured performance modes reconfigurable on-the-fly to optimize perception in different driving environments such as parking lots, city streets, and highways.